Importance of Thermal Ansys Analysis in the Design of Electronics

Ansys Thermal Analysis is the latest software aiding in engineering complex problems in designing various electrical equipment. This computational software analysis is being used extensively in studying the model design, simulation, and performance of various mechanical structures, fluid dynamics, and electronic devices to achieve unprecedented results, saving high costs on prototype studies. Let’s discuss further.

Importance of thermal analysis in electrical devices

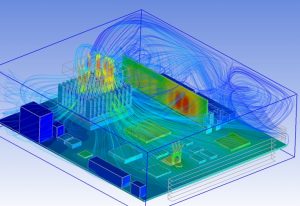

Many electrical device products transfer heat. When the heat transfer exceeds the standard ranges, the electrical product components fail to function. To evaluate the heat exchange process in various heat conductors before manufacturing, thermal analysis software is beneficial. It provides comprehensive analysis of heat conduction, convection, radiation, and transfer in electronic devices. It eliminates the prototype analysis time and investment.

Using Ansys, the engineers study the thermal behavior of the electrical device under various thermal conditions to know the withstand thresholds for heat dissipation. The information obtained through thermal analysis helps engineers and designers to make informed decisions about electrical product manufacturing.

Benefits of contacting thermal management companies

The thermal solutions companies offer thermal analysis services. These thermal management companies use comprehensive thermal analysis tools, including Flo THERM, to provide accurate thermal analysis. By contacting thermal management companies before production, manufacturing companies can avoid risk mitigation and compliance issues. And later device failures and losses. Manufacturing companies can rest assured of product reliability by conducting thermal analysis and optimizing electronics, effectively addressing identified potential overheating risks.

Additionally, the early Thermal Ansys analysis provides ample time for engineers to refine their designs and to test the thermal capacities in different conditions. Avoid last-minute design iteration pressure and delays in manufacturing.

Cooling solution in electronic devices

For effective heat exchange, most electrical devices include Phase Change Materials (PCM) in their manufacturing. PCM offers passive cooling solutions. By changing the matter state from solid to liquid, the PCM absorbs the heat, maintaining the devices and batteries at optimal temperatures. The Thermal Ansys Software helps to study the heat transfer in PCM materials.

To reduce production costs and to avoid compliance issues in industrial manufacturing, thermal analysis is the latest and fastest solution.

About Thermal Design Solutions:

Thermal Design Solutions is a renowned consultancy for thermal analysis of phase change material cooling devices used in automobiles, healthcare, the food industry, and buildings. This company's engineers implement thermal interface material technologies and the latest ANSYS thermal software to accurately study the heat transfer capacities in mobile devices and other electronics.

For more details, visit https://thermalds.com/

Comments

Post a Comment